FALL 2022

BRASS LAMP

WORK TYPEsolo

CONTEXTfiat lux studio, risd

TIME4 months, ~14 hours/week

in an industrial design studio, I sought to experiment with

manufacturing techniques in making new forms

brainstorming for this project centered around form before to create a truly minimal and seamless design—unlike engineering-first work.

brainstorming for this project centered around form before to create a truly minimal and seamless design—unlike engineering-first work.

WORK TYPEsolo

CONTEXTfiat lux studio, risd

TIME4 months, ~14 hours/week

in an industrial design studio, I sought to experiment with

manufacturing techniques in making new forms

brainstorming for this project centered around form before to create a truly minimal and seamless design—unlike engineering-first work.

brainstorming for this project centered around form before to create a truly minimal and seamless design—unlike engineering-first work.

CONCEPT

I decided on a symmetrical curved design that uses the weight of

the brass itself as the counterweight. all electronics and

wiring would be hidden within the thin frame of the lamp

itself—or separately on the power line.

TEST RUN

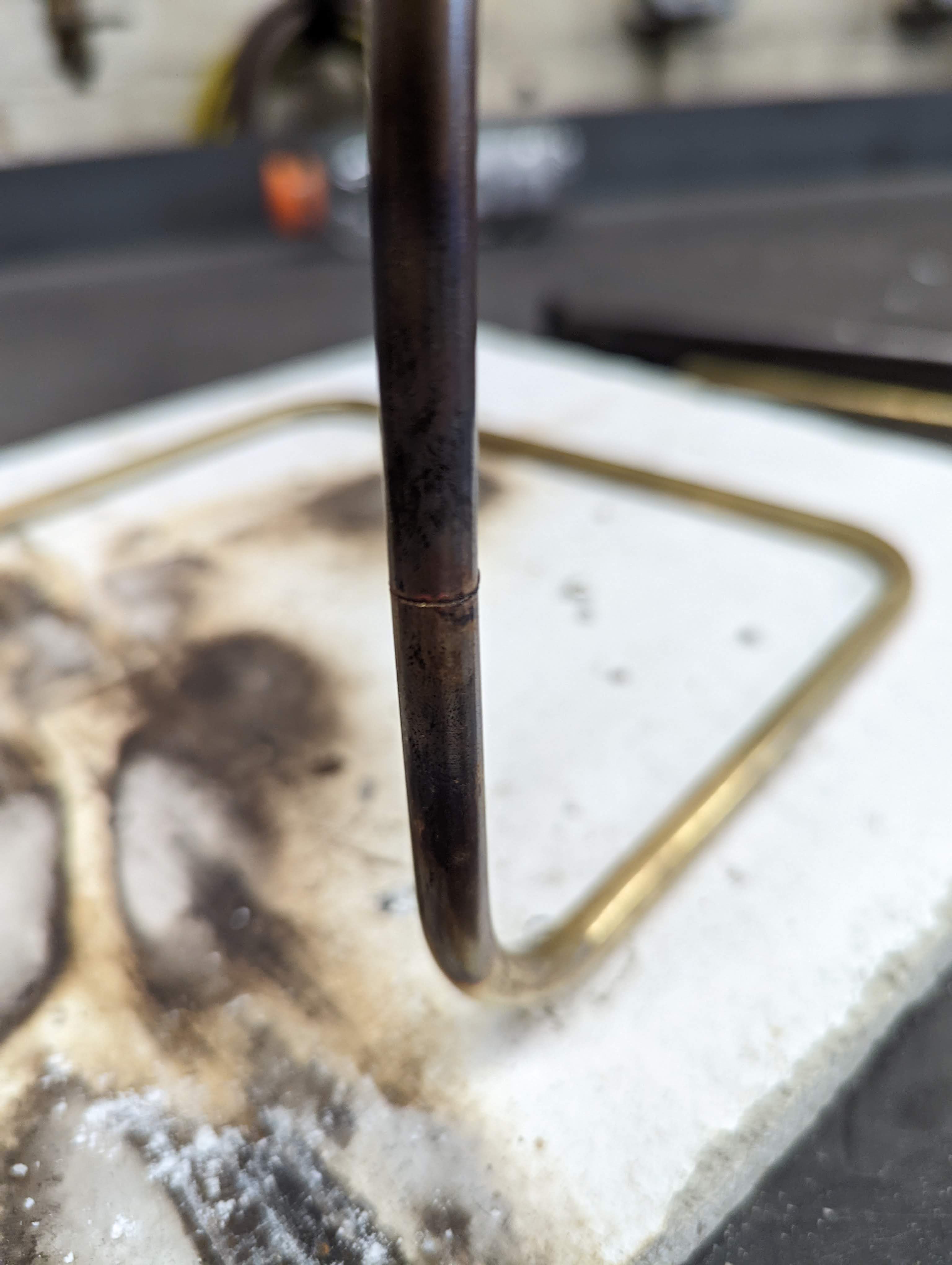

after test bends with various metal stocks, the first prototype

was made using 1/8" brass tube stock. the three-part brass was

held with friction at the base joints.

acrylic-welded acrylic pins acting as tubes held an flush

acrylic tube at the top.

a rigid test filament was directly pulled from an bulb. the

filament was too short and required too much power to run, but a

sense of the final product was there.

FULL PROTOTYPE

with some test bends under my belt, I went to work perfecting a

better set of brass parts. acrylic was changed to glass as

acrylic-weld proved unreliable.

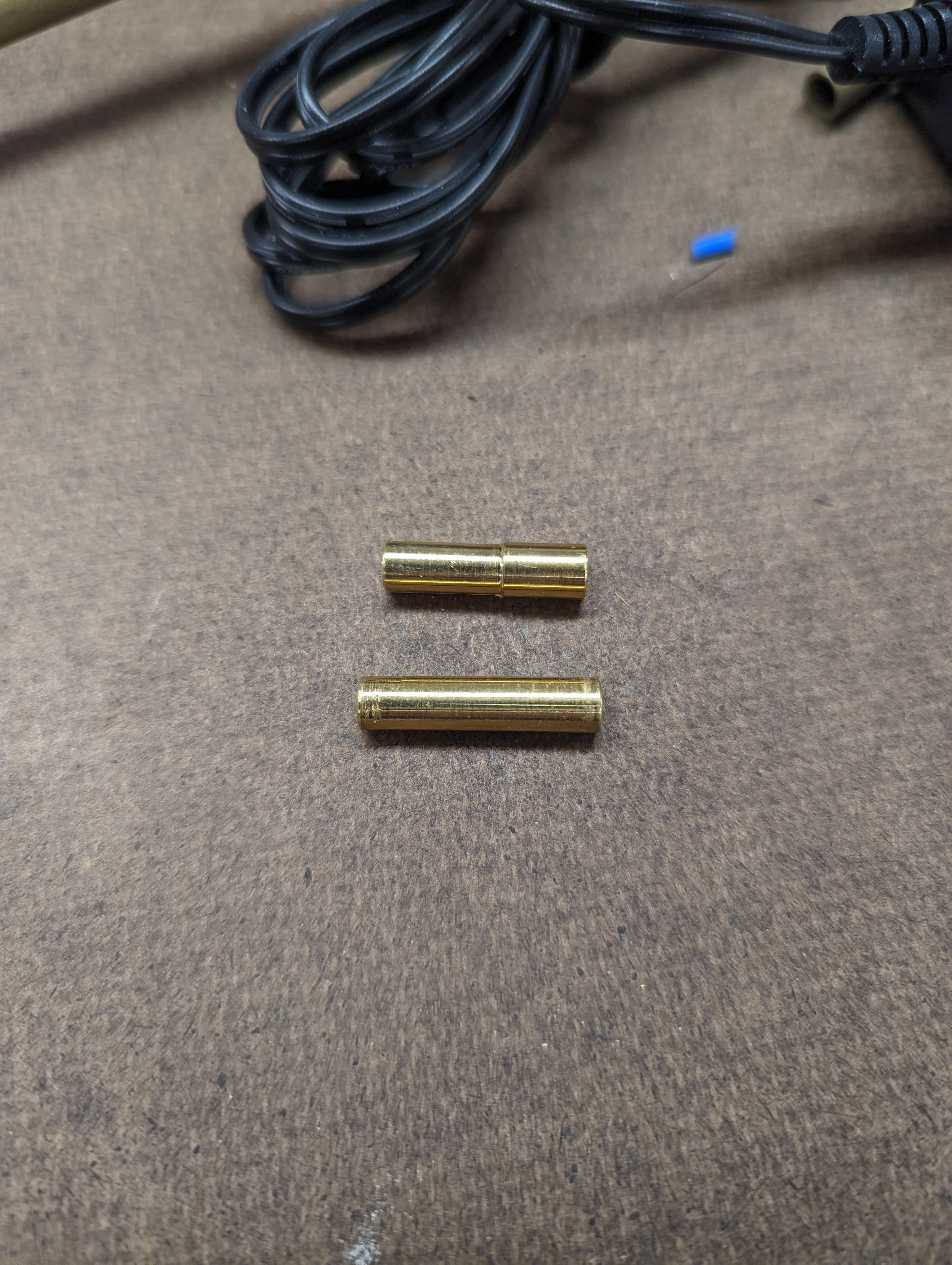

in addition to the arms and base, two of each style of pin was

lathed from tube stock. one stepped for fitting the brass to the

glass and one flush for fitting brass to brass.

the parts were soldered together with the joints.

finally, crossbar (shown below), which was used to link the

electronic connections and act as a capacitive switch, was added

via soldering.

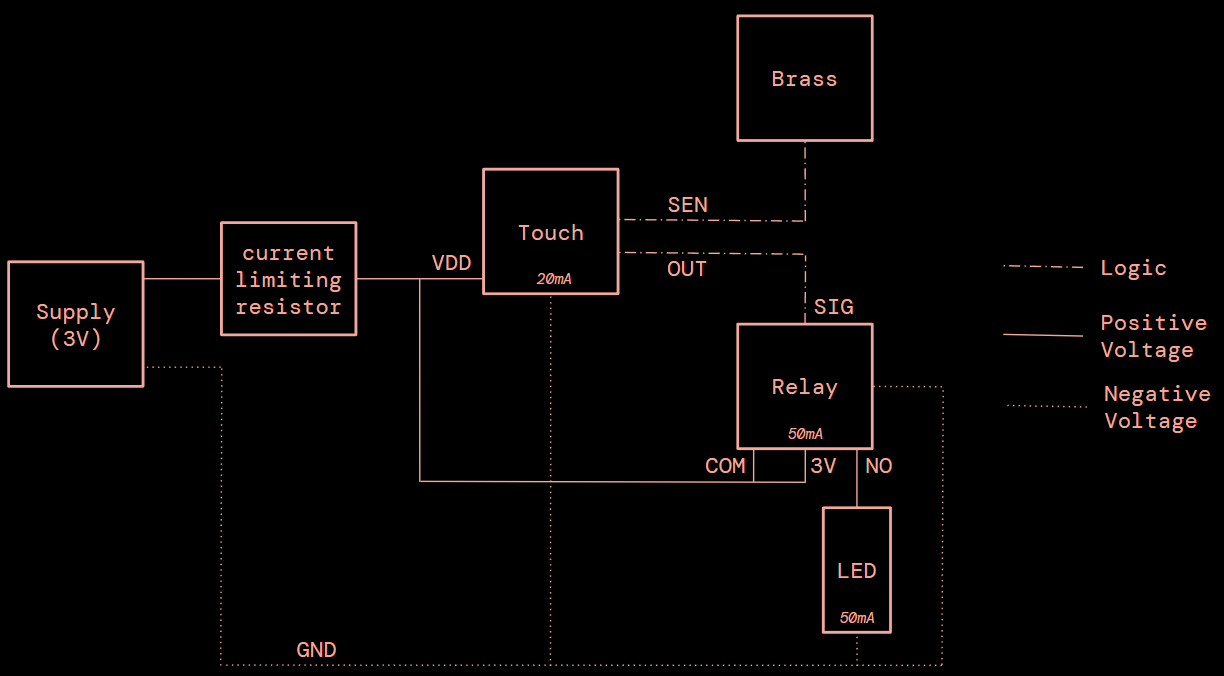

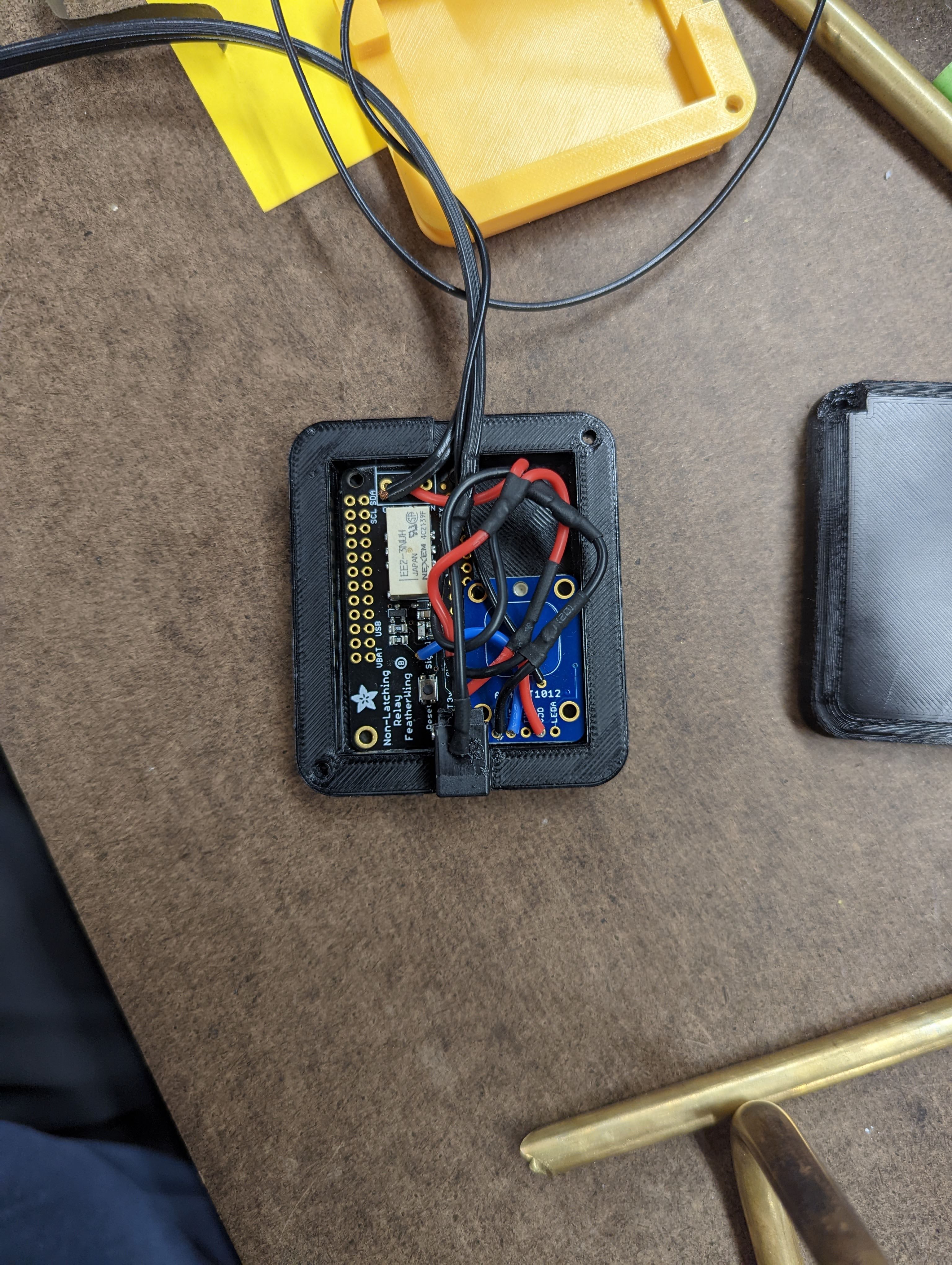

ELECTRONICS

a schema was drawn for the electronics, which were housed in a

small, custom box inline with the power. the electronics allow

for the touch-based operation of the lamp.

PRODUCT PHOTOS